The NAS, ISO, GJB pollution levels can be displayed in numbers, charts, etc.Ħ. Data USB transmission, system upgrade, etc.ĥ. Built-in PC, you can easily conduct comprehensive data query without connecting to another computer.Ĥ. There are online and sampling testing model, which can be used in both the laboratory and online.ģ. The laser sensor has high detection accuracy.Ģ. Can be widely used in aerospace, electric power, petroleum, chemical, transportation, port, metallurgy, machinery, automobile manufacturing and other fields.ġ. This portable ISO 44 oil paritcle counter can detect aviation kerosene, mineral oil, synthetic oil, phosphate oil and water solution, including hydraulic oil, lubricating oil, transformer oil (insulating oil), turbine oil, gear oil, engine Oil, etc. (2) the ISO Solid Contaminant Code (SAE J1165) and (3) the National Aerospace Standard Code (NAS 1638).KR-B oil particle counter is portable type, can be used to detect the amount and distribution of solid particles in the solution, for example: can be used for on-line monitoring, can also be used for off-line detection of sample bottles (lab mode), can also be used for monitoring the filter effect of the filter and other occasions. We offer three types of automatic particle counting tests: (1) ISO 4406, presently the most commonly used code to express the cleanliness of hydraulic fluids.

For the total mass of particles by filtration, consider ASTM D4898. If you are interested in the total volume of sediment consider ASTM D2273, FTM 3101 or ASTM D91. Optical microscopy helps to identify the types of particles in cases of high automatic particle counts. Automatic optical particle counting is the best choice for most samples – it usually yields accurate results and gives an in-depth breakdown of particle sizes in the sample. Related tests offered by Petro-Lube: We offer optical microscopy tests (ARP 598B, WQTM 611, ASTM F312, FTM 3013, FTM-3009) and Automatic Optical Particle Counting (ISO 4406, ASTM D6786, FTM 3012, SAE J1165, SAE 749) to determine the cleanliness of fluids.

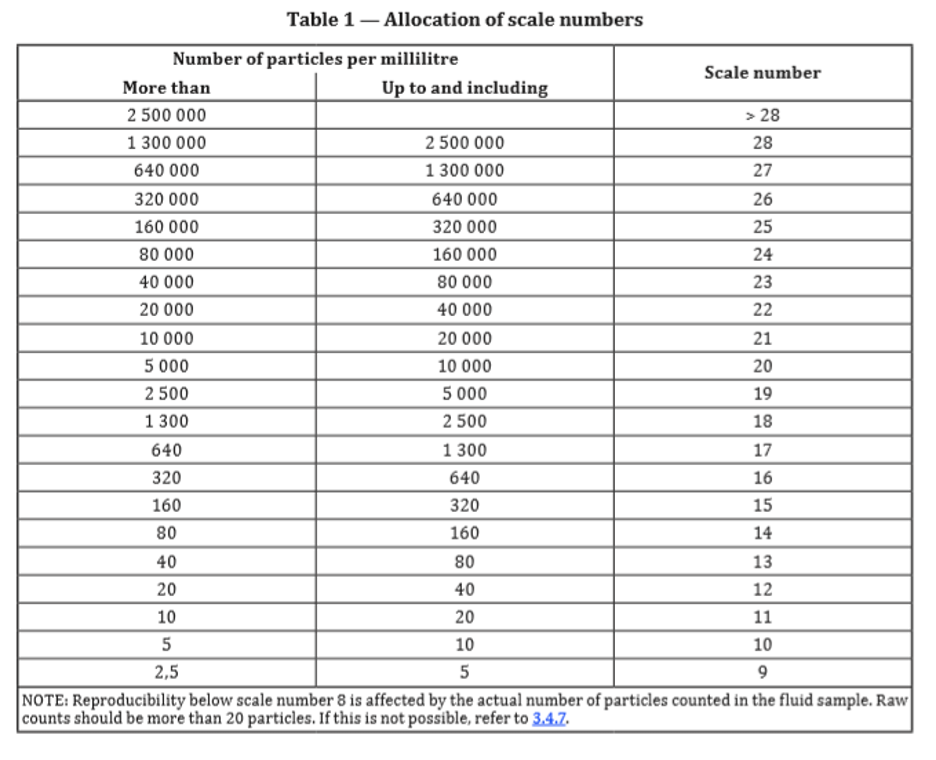

Using an Automatic Optical Particle Counter as per the method, the number of particles in each size category is determined and reported along with the ISO Cleanliness Code. In this method, the concentration of particles in 3 size categories (≥ 4 µm, ≥ 6 µm and ≥14 µm) is determined and used to establish the ISO Cleanliness Code rating. The ISO Cleanliness Code is a standardized system developed to give a comparative value of the number of particles in a fluid. Contamination of these fluids, from environmental debris, microbial growth, wear, fluid degradation or other sources, may decrease system efficiency, damage components and potentially cause system failure. Hydraulic systems use pressurized hydraulic fluids to transmit power. ISO 4406 – Hydraulic Fluid Power – Fluids-Method for Coding the Level of Contamination by Solid Particles

0 kommentar(er)

0 kommentar(er)